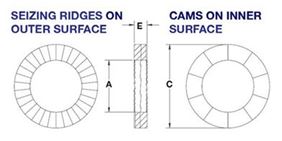

TEC Series® washers keep joints secure using tension, not friction as with traditional washers. TEC washers consist of a pair of washers with cams on one side and seizing ridges on the other. The cam sides are mated together with a mild adhesive, and installed between the bolt head or nut and the joint material.

As the bolt or nut is tightened, the seizing ridges cause one half of the washer to be seated to the bolt or nut, while the other half is seated to the joint material.

Features and Benefits- Heavy-duty, self-locking design

- For use with bolts up to Class 10.9, Grade 8

- Available in sizes from #8 (M4) to 1-3/8" (M36)

- Available in SCM435 or 4130 Alloy Steel

- Provided in preassembled glued pairs

- Easy to install with standard tools

- No retightening needed after installation

- Reusable

- Vibration proof according to MIL-STD-1312-7

Quality and TraceabilityTEC Series® washers are thoroughly tested in several stages of production to ensure a high level of quality Sherex customers have come to expect. Each TEC Series washer is laser etched with a production lot number, part size, and coating to enable full traceability and easy identification.

TEC Series® washers are manufactured in an ISO-Certified Facility and are fully RoHS compliant.

Installation - To install the TEC Series® Washer, place the preassembled pair between the nut or bolt and the joint material.

- As the nut or bolt is tightened, one half of the washer pair will be seated to the joint material and the other half will be seated to the nut or bolt.

- Install TEC Series® washers using standard tools according to TEC Series Torque Guidelines. Retightening is not needed.

- The use of lubricants is highly recommended when installing TEC Series® washers. A high quality lubricant designed to prevent seizing will reduce friction during installation and improve the consistency of clamp load in joints.

Torque GuidelinesWhen installing TEC Series® Washers in a common application, expect an increase in required torque over recommended installation torque to achieve proper clamp load and maximum joint safety. Due to varying installation conditions and customer specific applications, additional information and torque recommendations are available by contacting Engineering support at Sherex.

Removal and ReuseRemoving TEC Series® washers requires no special tools or procedure. Simply untighten the joint in the normal method and check the washer to ensure cam faces disengage.

While TEC Series® washers are usually reusable, washers should always be inspected for deformation or excessive wear before reuse. If washers appear deformed or heavily worn, discard and use a new pair.

Application ExamplesTEC Series® wedge locking washers can be used to protect joint integrity in a wide variety of joint types, including:

Tapped Hole

Counter Bore

Stud Bolt

Large Hole (For large/slotted holes and painted or soft contact surfaces, use Enlarged OD TEC Series Washers)

TEC Series

® wedge locking washers are not recommended for mating surfaces that are not locked in place or are harder than the washers. TEC Series washers are not recommended for use in non-preloaded joints.

Proven ApplicationsTEC Series® Wedge Locking Washers outperform conventional, split-ring, and other style washers in a wide variety of high stress, corrosive, and vibration-sensitive applications including:

- Agriculture Equipment

- Automotive

- Construction Equipment

- Heavy Rail

- Aerospace and Defense

- Mining and Drilling Equipment

- HVAC

- Solar and Wind

- Waste Management

Proven ResultsTEC Series® Wedge Locking Washers have been tested on a Junker Vibration Machine. The Junker test, considered the most severe vibration test for bolted joints, is used to determine the point at which a bolted joint loses its preload when subjected to shear loading due to transverse vibration.

When tested against a standard washer using the Junker test, TEC Series® wedge locking washers remained secure under severe vibration conditions, while the standard washer loosened significantly.

Additional InformationWhen the joint experiences vibration, the bolt or nut attempts to loosen. Since one half of the washer is seated to the bolt or nut, it attempts to rotate as well.

Because of the cam angle (α) of the washers is greater than the thread pitch (ß) of the bolt, a wedge effect is created by the cams, preventing the bolt or nut from rotating loose. Clamp load is maintained and the joint remains secure.

NoteWeight and thickness of pairs will vary slightly with gauge of metal.

Coated in Delta Protekt® KL100 and V H302 GZ.

Custom designs available.

Sold in full cartons only. Less than full carton quantities are available for purchase through TEC Series Distributors.