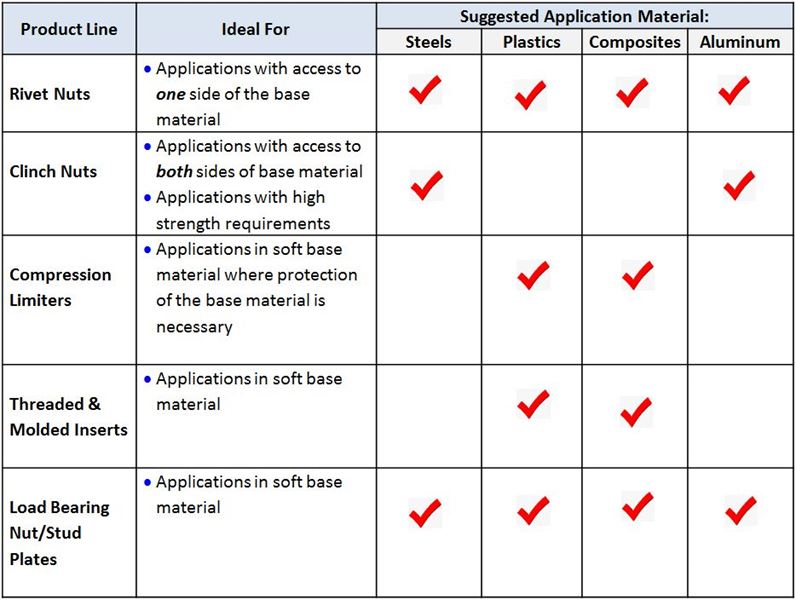

Sherex offers a variety of products for thin sheet metal, plastic, and composite attachments. Our engineering and R&D teams understand manufacturing processes and material and performance requirements, and have created a product portfolio that addresses a multitude of specific requirements.

Our fastening solutions for thin sheet applications rely on mechanically attaching a threaded component to the base material.

Reliability, performance, and value are critical -- our solutions deliver consistent, high strength attachment points over the lifetime of the product at the lowest-total-installed cost relative to alternative solutions. We consider the manufacturing scenario, the fastener, and the installation method when designing your custom solution, taking into account what combination provides the best value with the highest performance.

NEW in 2024: Sherex now provides ATLAS® rivet nuts in its catalog! ATLAS® rivet nuts by PennEngineering® include its popular SpinTite®, MaxTite®, and Plus+Tite® line of rivet nuts. These products and more are now available through Sherex!

For the ATLAS® catalog -- click here>>

To learn more about the Sherex-PennEngineering® partnership -- click here>>

/Asset/fasteners-for-thin-sheet-attachments.jpg

Sherex's TEC Series® and Disc-Lock brand of wedge locking washers and nuts utilize tension, rather than traditionally-used friction, to secure fastened joints in high vibration and load applications. This results in secure joints that are unable to loosen through vibration. Our wedge-locking washers are used in a variety of vibration intensive industries and can even be found to be useful around the house to secure those pesky nuts and bolts that need to be retightened every so often.

How Locking Washer Technology Works

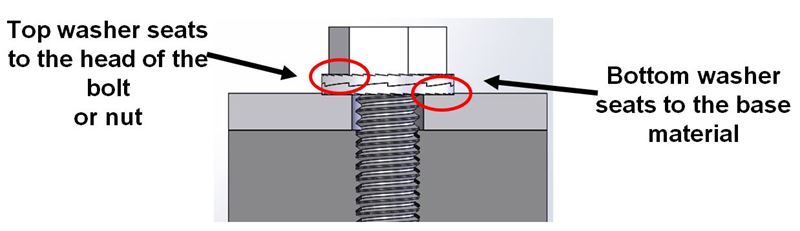

TEC Series and Disc-Lock Washers are offered in glued pairs; each washer has a cams on one side and radial teeth on the other side. The cam sides are glued together. During installation, the radial teeth cause half of the washer to be seated to the bolt or nut, and half to be seated to the base material.

When the joint is exposed to heavy load or vibration, the bolt or nut will attempt to loosen. Because the TEC Series or Disc-Lock washer’s radial teeth are seated to the base material and the bolt or nut, the loosening movement is forced into the cams between the washer pair.

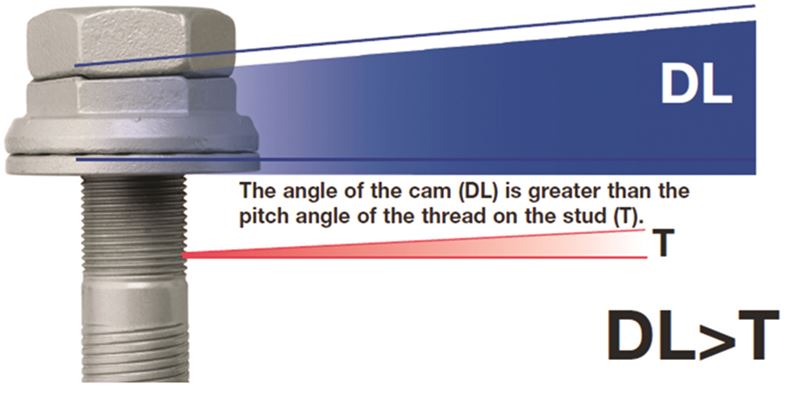

Because the cam angles are greater than the thread pitch, a wedge effect is created by the cams, preventing the bolt or nut from rotating loose.

How Locking Nut Technology Works

Disc-Lock Nuts are two and three piece nuts that utilize the same cam wedge locking technology: when the joint is subjected to heavy shock or vibration, the interlocking cams create a wedge effect because the cam angles are greater than the thread pitch, securing the joint.