TEC Series wedge-locking washers are recommended for applications where fasteners and washers may need to be removed and/or reused.

How TEC Series Washers Work

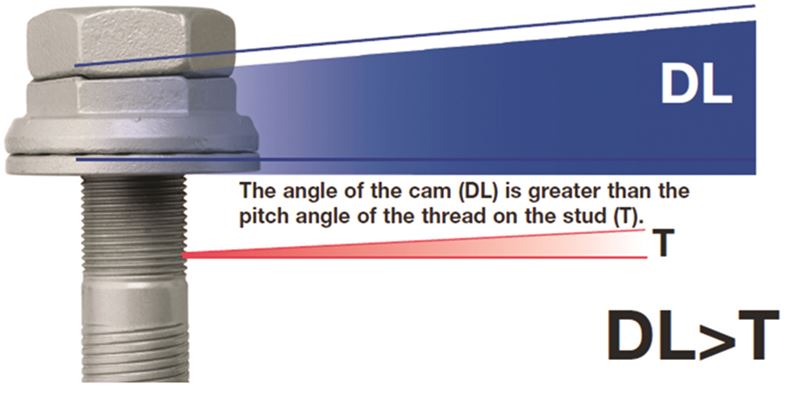

TEC Series washers are designed with cams on one side and radial teeth on the other. During installation, the radial teeth cause one-half of the washer to be seated to the bolt or nut, while the other half is seated to the joint material. When subjected to load or vibration, traditional fasteners can loosen over time. However, with TEC Series washers, the radial teeth are firmly seated to the mating surfaces to prevent any movement in the loosening direction. This is where the unique cam design comes into play. The cam angle of the washers is greater than the thread pitch angle of the bolt, creating a wedge effect that prevents the bolt or nut from rotating loose. As a result, the clamp load is maintained, and the joint remains securely fastened.

Key Features and Benefits

Wedge locking washers, recommended for applications with permanent joints, where fasteners will NOT need to be removed

Disc-Lock's Wedge Locking Nuts come in 2 and 3-piece designs that are patented, heavy duty, and self-locking.

These wedge locking nuts outperform standard nuts in a wide range of high-stress, corrosive, and vibration-sensitive applications.

The M22 Safety Wheel Nut is one of Disc-Lock's most popular products, as its specifically designed to prevent wheel loss on commercial vehicles such as trucks, trailers, and buses.

Here is a snapshot of some of the features and benefits of all of Disc-Lock's Wedge Locking Nuts products: