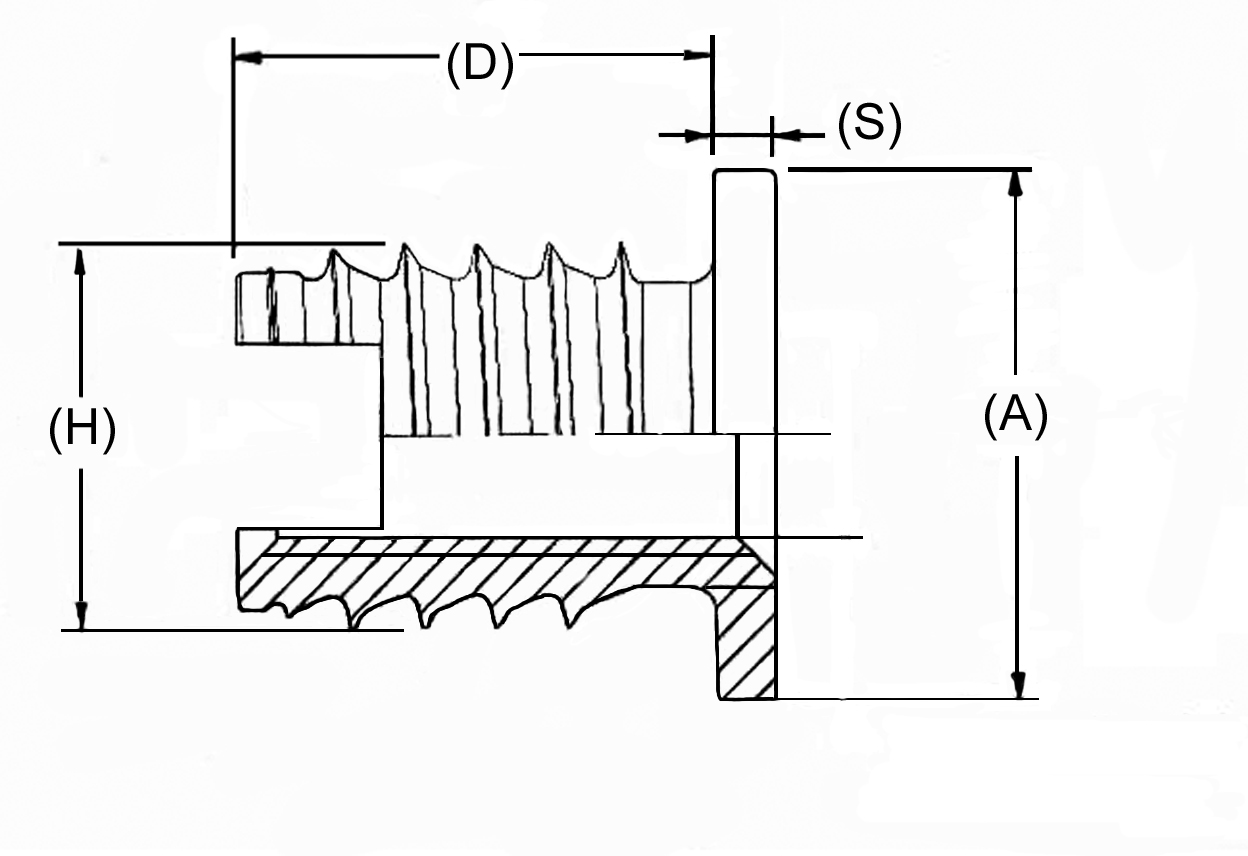

- Designed for SMC, Thermoset, and other brittle plastics

- Flange provides larger bearing surface

- Installed with a tap wrench or drill press with tapping head

- Class 2B per ANSI/ASME B1.1

Thread In - this method is reserved for the B1T and B2T insert styles. A tool will thread the inserts into the boss hole and the slots on the body will cut a thread into the plastic. This method is good for thermosets and other rigid plastics. An adhesive can be added to the outside thread to bond the insert into the plastic; further improving insert retention within the base material.

Applications for Threaded Inserts for Plastic vary from communication equipment, the automotive industry, computer industry, and anywhere where strong durable threads are required in plastics.

Unit of Measure

Dimensions |

N/A

|

Thread Size |

N/A #8-32 UNC |

ØH ±0.004 |

N/A 0.276 Inch |

D± 0.005 |

N/A 0.315 Inch |

ØA ±0.005 |

N/A 0.394 Inch |

S ±0.004 |

N/A 0.039 Inch |

Hole Depth

|

N/A 0.378 Inch |

Minor Diameter

|

N/A .130 / .139 Inch |

Recommended Hole Size for Thermoset Material

|

N/A 0.262 Inch |

|

N/A

B2T-0832-315.pdf |