-

Fasteners for Thin Sheet Attachments

fasteners-for-thin-sheet-attachments

-

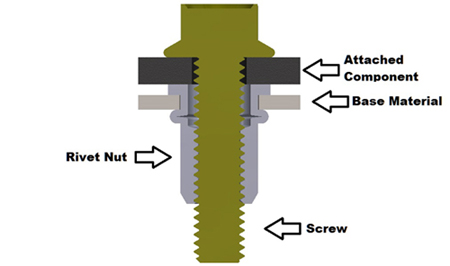

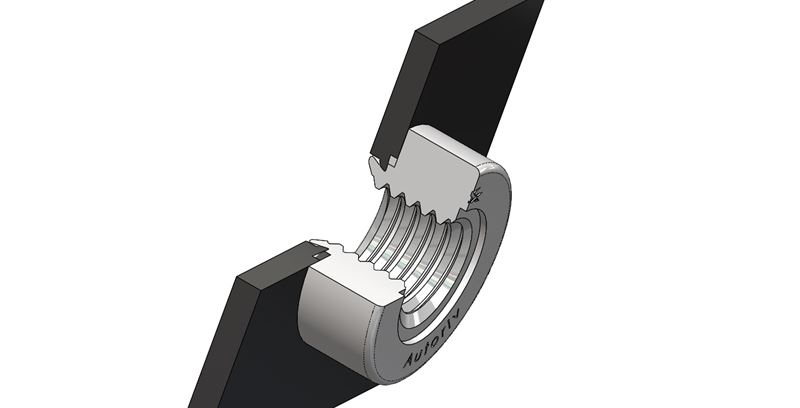

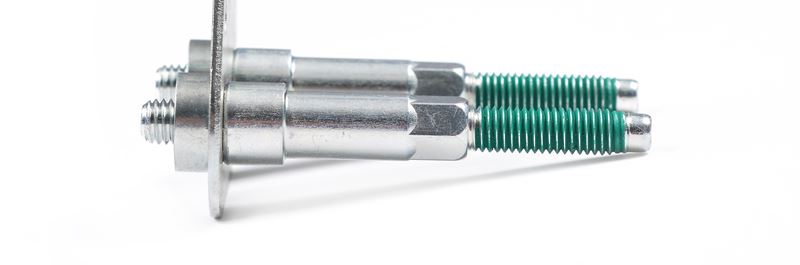

Blind Rivet Nuts

Blind Rivet Nuts provide load-bearing threads in thin sheet materials that are too thin for a tapped thread. They are called “blind” because they can be installed from one side of the workpiece. Once the rivet nut is installed, additional components can be attached using threaded fasteners.

NEW in 2024: Sherex now provides ATLAS® rivet nuts in its catalog! ATLAS® rivet nuts by PennEngineering® include its popular SpinTite®, MaxTite®, and Plus+Tite® line of rivet nuts. These products and more are now available through Sherex!

For the ATLAS® catalog -- click here>>

To learn more about the Sherex-PennEngineering® partnership -- click here>>

Benefits / Advantages- Provide a strong thread in thin materials that cannot be tapped

- Easy to disassemble and reassemble

- Once installed, additional components with threaded fasteners can be attached

- Pre-painted material will not be damaged during the installation process

- Available in many different styles and materials

- Ideal replacement for weld nuts:

- More efficient, simple installation

- Will not distort base material

- Eliminates weld splatter, toxic fumes, and other by-products of the welding process

- Can be installed in many different kinds of material including steel, plastic, composites, and fiberglass

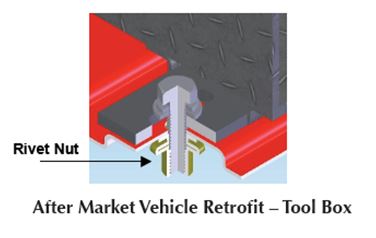

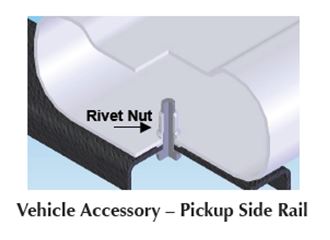

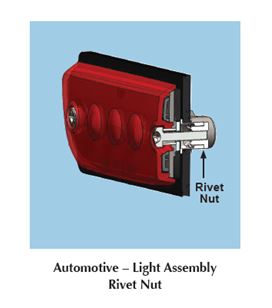

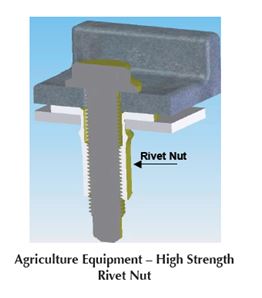

Rivet Nut Application Examples

Sherex provides a broad offering of rivet nuts to meet the requirements of many different types of applications.

Our products are available in steel, stainless steel, or aluminum materials, with a variety of head types (wedge, keyed, countersunk), and with closed ends and/or sealed heads. -

Fasteners for Plastics & Composites

Sherex offers a variety of fasteners for structural attachments in plastic and composites. Our R&D and engineering teams understand the challenges and requirements of fastening plastics and composites, and have developed solutions specific to these applications.

-

Clinch Nuts

Clinch nuts are self-clinching, internally threaded nuts that are pressed into the base material.

Ideal for applications:- With access to both sides of the base material

- With high thread strength and superior pull-out force requirements

- With metal base materials: steel, stainless steel, and aluminum

- To learn more about clinch nuts, click here

-

Load Bearing Nut Plates and Stud Plates

Load Bearing Nut and Stud Plates are metal plates with pre-installed fasteners that provide increased joint performance in lightweight materials.

Ideal for applications:- Where high performance in plastics or composite base material in required

- Where increased efficiency on the production line is necessary

-

Threaded Inserts

Threaded Inserts provide a strong threaded attachment point in soft or hard plastics.

Ideal for applications:- In soft or hard plastics or composites

- Where post-mold installation is required

-

Molded Inserts

Molded Inserts provide a strong threaded attachment point in soft or hard plastics.

Ideal for applications:- In soft or hard plastics or composites

- Where inserts can be installed during the molding process to achieve a stronger engagement with base material

-

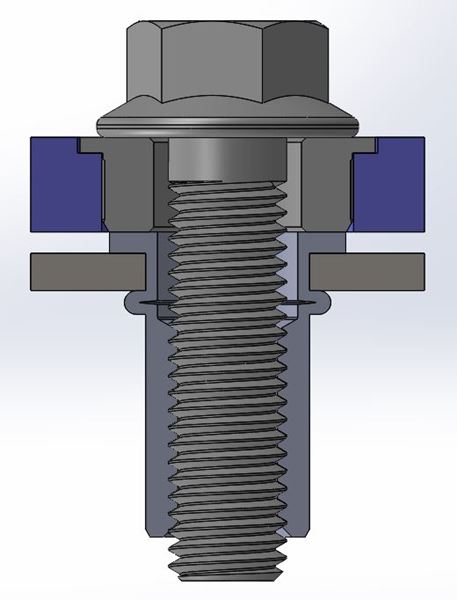

Compression Limiters

Compression Limiters are used in conjunction with fasteners to prevent overstressing of the base material and clamp loss of the fastened joint

Ideal for applications:- In soft or hard plastics or composites

- Where preventing clamp loss is critical

- Where protecting base material from overstressing is critical