- All Categories

-

Fasteners for Thin Sheet Attachments

-

Blind Rivet Nuts

-

Round Body Rivet Nuts

-

Optisert Series

- Optisert -- Open End (Metric) | Steel (308 Items)

- Optisert -- Open End (Inches) | Steel (144 Items)

- Optisert -- Open End (Metric) | Stainless Steel (18 Items)

- Optisert -- Open End (Inches) | Stainless Steel (27 Items)

- Optisert -- Closed End Sealed (Metric) | Steel (302 Items)

- Optisert -- Closed End Sealed (Inches) | Steel (144 Items)

-

CAL Series

- CAL Series - Steel (Inches) | Large Flange Knurled Body Thin Wall Series (268 Items)

- CAL Series - Steel (Metric) (368 Items)

- CAL Series - Aluminum (Inches) (132 Items)

- CAL Series - Aluminum (Metric) (368 Items)

- CAL Series - Stainless Steel (Inches) (10 Items)

- CAL Series - Stainless Steel (Metric) (6 Items)

-

CAK Series

- CAK Series - Steel (Inches) | Small Flange Knurled Body Thin Wall Rivet Nut (2256 Items)

- CAK Series - Steel (Metric) (293 Items)

- CAK Series - Aluminum (Inches) (2256 Items)

- CAK Series - Aluminum (Metric) (293 Items)

- CAK Series - Stainless Steel (Metric) (10 Items)

-

CA Series

- CA Series - Steel (Inches) | Heavy Duty Rivet Nut Flat Head, Large Flange, Smooth Shank (193 Items)

- CA Series - Aluminum (Inches) (193 Items)

- CA Series - Stainless Steel (Inches) (193 Items)

-

CAO Series

- CAO Series - Steel (Inches) | Small Flange, Smooth Body, Thin Wall Rivet Nut (134 Items)

- CAO Series - Steel (Metric) (162 Items)

- CAO Series - Aluminum (Inch) (134 Items)

- CAO Series - Aluminum (Metric) (162 Items)

-

CFW/CAW Series

- CFW/CAW Series - Steel (Inches) | Cadmium Free Diamond Knurled Body 360° Swaging Rivet Nut (7 Items)

- CFW/CAW Series - Steel (Metric) (5 Items)

- CFW/CAW Series - Aluminum (Inches) (7 Items)

- CFW/CAW Series - Aluminum (Metric) (5 Items)

- CFW Series - Stainless Steel (Inches) (7 Items)

- CFW/CAW Series - Stainless Steel (Metric) (5 Items)

-

CFT/CAT Series

- CFT/CAT Series - Steel (Inches) | Cadmium Free Small Flange 360° Swaging Rivet Nut (9 Items)

- CFT/CAT Series - Steel (Metric) (7 Items)

- CFT/CAT Series - Aluminum (Inches) (9 Items)

- CFT/CAT Series - Aluminum (Metric) (7 Items)

- CFT Series - Stainless Steel (Inches) (9 Items)

- CFT Series - Stainless Steel (Metric) (7 Items)

-

CPB Series Rivet Nuts

- CPB Series - Steel (Inches) (162 Items)

- CPB Series - Steel (Metric) (325 Items)

-

CPN Series Rivet Nuts

- CPN Series - Steel (Inches) | Straight Shank Slotted Body Rivet Nut (162 Items)

- CPN Series - Steel (Metric) (325 Items)

-

UPO Tubtara®

- UPO Series - Steel (18 Items)

- UPO Series - Aluminum (15 Items)

- UPO Series - 304 Stainless Steel (11 Items)

- UPO Series - 316 Stainless Steel (3 Items)

-

UFO Tubtara®

- UFO Series - Steel (13 Items)

- UFO Series - Aluminum (11 Items)

- UFO Series - 304 Stainless Steel (6 Items)

-

UKO Tubtara®

- UKO Series - Steel (8 Items)

- UKO Series - Aluminum (4 Items)

- UKO Series - 304 Stainless Steel (5 Items)

- UKO Series - 316 Stainless Steel (3 Items)

- UKO Series (Inches) - 304 Stainless Steel (3 Items)

-

UPO RS Tubtara®

- UPO RS Series - Steel (10 Items)

-

UFO RS Tubtara®

- UFO RS Series - Steel (10 Items)

-

CLM

- CLM Series - Steel (5 Items)

- CLM Series - Aluminum (5 Items)

-

CKM

- CKM Series - Steel (5 Items)

- CKM Series - Aluminum (5 Items)

-

Optisert Series

-

Hex Body Rivet Nuts

-

FHL Series

- FHL Metric Series (271 Items)

- FHL Inch Series (1042 Items)

-

FHK Series

- FHK Metric Series (307 Items)

- FHK Inch Series (1181 Items)

- LRGH Series (4 Items)

-

CAH Series

- CAH Series - Steel (Inches) (2257 Items)

- CAH Series - Aluminum (Inches) (2256 Items)

- CAH Series - Steel (Metric) (293 Items)

- CAH Series - Aluminum (Metric) (293 Items)

-

HUKO Series

- HUKO Series (Inches) (3 Items)

- HUKO Series (Metric) (8 Items)

- HUPO Series (10 Items)

-

HUKO Stainless Series

- HUKO Series - 304 Stainless Steel (6 Items)

- HUKO Series - 316 Stainless Steel (3 Items)

-

HUPO Stainless Series

- HUPO Series - 304 Stainless Steel (4 Items)

- HUPO Series - 316 Stainless Steel (3 Items)

-

CFH Series

- CFH Series - Steel (Inches) (15 Items)

- CFH Series - Steel (Metric) (12 Items)

- CFHD Series (6 Items)

-

FHL Series

-

Large Size Rivet Nuts

- Round Body Large Size Rivet Nuts (5 Items)

- Full Hex Body Large Size Rivet Nuts (4 Items)

-

RIV-FLOAT® Rivet Nuts

- RIV-FLOAT® Rivet Nuts (251 Items)

- RIV-FLOAT®-Short Series (6 Items)

- Rivet Nut Studs

-

NAS/MS Rivet Nuts

- NAS 1329 Flat Head Style (46 Items)

- NAS 1330 Countersunk Head Style (46 Items)

- Specialty Fastener Solutions (13 Items)

-

ATLAS MaxTite® Rivet Nuts

-

Countersunk Head

- Countersunk Head Threaded Insert - Open End Keyless - Unified (460 Items)

- Countersunk Head Threaded Insert - Open End Keyed - Unified (460 Items)

- Countersunk Head Threaded Insert - Closed End Keyless - Unified (460 Items)

- Countersunk Head Threaded Insert - Closed End Keyed - Unified (460 Items)

- Countersunk Head Threaded Insert - Open End Keyless - Metric (386 Items)

- Countersunk Head Threaded Insert - Open End Keyed - Metric (386 Items)

- Countersunk Head Threaded Insert - Closed End Keyless - Metric (386 Items)

- Countersunk Head Threaded Insert - Closed End Keyed - Metric (387 Items)

-

Flathead

- Flathead Threaded Insert - Open End Keyless - Unified (532 Items)

- Flathead Threaded Insert - Open End Keyed - Unified (532 Items)

- Flathead Threaded Insert - Closed End Keyless - Unified (532 Items)

- Flathead Threaded Insert - Closed End Keyed - Unified (532 Items)

- Flathead Threaded Insert - Open End Keyless - Metric (386 Items)

- Flathead Threaded Insert - Open End Keyed - Metric (386 Items)

- Flathead Threaded Insert - Closed End Keyless - Metric (386 Items)

- Flathead Threaded Insert - Closed End Keyed - Metric (386 Items)

-

Countersunk Head

-

Round Body Rivet Nuts

- Fasteners for Plastics & Composites

-

Clinch Nuts

- ACN Series High Strength Clinch Nut Series (6 Items)

- ARN Series Universal Riveting Nut Series (5 Items)

- ASN Series Serrated Style Clinching Nut Series (4 Items)

- Load Bearing Nut Plates and Stud Plates

- Compression Limiters

-

Blind Rivet Nuts

-

Vibrational Loosening Prevention - Wedge Locking Technology

- TEC Series® Wedge Locking Washers

-

Disc-Lock® Wedge Locking Washers

- Disc-Lock® Carbon Steel Washers (17 Items)

- Disc-Lock® Stainless Steel Washers (10 Items)

-

Disc-Lock® Wedge Locking Nuts

- Disc-Lock® Two-Piece Wedge Locking Nuts (18 Items)

- Disc-Lock® Safety Wheel Nut

- Disc-Lock™ Heavy Hex Nuts (6 Items)

- Disc-Lock® Bolts

-

Fastener Installation Systems

-

Rivet Nut Hand Tools

- Rivet Nut Hand Tool (16 Items)

- DLHT Double Lever Hand Tool (12 Items)

- DRHT Double Ratchet Hand Tool (15 Items)

- LHF 202 Hand Tool

-

Pneumatic Tools (Spin-Spin)

- SSG 800 Pistol Style Series (20 Items)

- SSG 900 Inline Style Series (17 Items)

- SSG 910 Inline Right Angle Style Series (17 Items)

-

Hydro-Pneumatic Tools

- MS 100 Rivet Nut Installation Tool 5/16-18-1/2-13 (M8-M14) (12 Items)

-

FLEX-5 Series Rivet Nut Installation Tool 4-40 to 3/8-24 (M3 to M10)

- FLEX-5S Pull to Stroke Installation Tool (17 Items)

- FLEX-5P Pull to Pressure Installation Tool (17 Items)

- FLEX-18 Rivet Nut Installation Tool 5/16-18 - 3/4-10 (M8-M20) (12 Items)

- Automation

-

Rivet Nut Hand Tools

-

Fasteners for Thin Sheet Attachments

Disc-Lock® Carbon Steel Washers

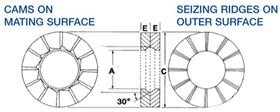

Disc-Lock® Wedge Locking Washers

Features & Benefits

Disc-Lock® Locking Washer Junker Test

Disc-Lock® Wedge Locking Washers have been tested on a Junker Vibration Machine. The Junker test considered the most severe vibration test for bolted joints according to DIN 65151, is used to determine the point at which a bolted joint loses its preload when subjected to shear loading due to transverse vibration.

When tested against a standard washer using the Junker test, Disc-Lock® Wedge Locking Washers remained secure under severe vibration conditions, while the standard washer loosened significantly.

Proven Applications

Disc-Lock® Wedge Locking Washers outperform conventional, split-ring, and other style washers in a wide variety of high stress, corrosive, and vibration-sensitive applications including:

When installing Disc-Lock® Washers in a common application, expect an increase in required torque over recommended installation torque to achieve proper clamp load and maximum joint safety. Due to varying installation conditions and customer-specific applications, additional information and torque recommendations are available by contacting Engineering support at Disc-Lock®.

Note

Weight and thickness of pairs will vary slightly with gauge of metal.

- Heavy-duty, self-locking design

- For use with bolts up to Class 10.9, Grade 8

- Available in sizes from 1/4" (M6) to 1-1/2" (38 MM) Other sizes available by special order.

- Available in 1010 Carbon Steel

- Carbon Steel washers are case hardened and coated with RoHS-compliant Delta Protekt®

- Provided in pre-assembled, glued pairs

- Easy to install with standard tools

- No re-tightening needed once installed

- Vibration proof according to MIL-STD-1312-7

Disc-Lock® Locking Washer Junker Test

Disc-Lock® Wedge Locking Washers have been tested on a Junker Vibration Machine. The Junker test considered the most severe vibration test for bolted joints according to DIN 65151, is used to determine the point at which a bolted joint loses its preload when subjected to shear loading due to transverse vibration.

When tested against a standard washer using the Junker test, Disc-Lock® Wedge Locking Washers remained secure under severe vibration conditions, while the standard washer loosened significantly.

Proven Applications

Disc-Lock® Wedge Locking Washers outperform conventional, split-ring, and other style washers in a wide variety of high stress, corrosive, and vibration-sensitive applications including:

- Agriculture Equipment

- Automotive

- Construction Equipment

- Heavy Rail

- Logging Equipment

- Marine

- Military

- Mining

- Oil Drilling Equipment

- Solar

- Wind

- Waste Management

- To install the Disc-Lock® Washer, place the preassembled pair of washers between the nut and the joint material.

- As the nut is tightened, one half of the Disc-Lock® Washer is seated to the joint material and the other to the nut.

- Disc-Lock® Washers should only be used against flat, relatively smooth metal surfaces.

- If the joint material is not metal, the Disc-Lock® washer may be used by securing the metal plate to the joint material in such a manner that the metal plate will not rotate.

- A torque wrench is not required to install Disc-Lock® Washers.

- An air-gun can be used when installing and removing Disc-Lock® Washers.

- If installed correctly, the Disc-Lock® Washer will ensure that the fastener remains secure, and will not require any re-tightening.

When installing Disc-Lock® Washers in a common application, expect an increase in required torque over recommended installation torque to achieve proper clamp load and maximum joint safety. Due to varying installation conditions and customer-specific applications, additional information and torque recommendations are available by contacting Engineering support at Disc-Lock®.

Note

Weight and thickness of pairs will vary slightly with gauge of metal.

- Coated in Delta Protekt® KL100 and VH302 GZ.

- Disc-Lock® Wedge Locking Washers are also available through our Made in the U.S.A. product line

Unit of Measure

| Items |

DL-M3-#6 Disc-Lock™ 0.150 Inch (in) Inner Diameter (A) Carbon Steel Washer |

DL-M4-#8 Disc-Lock™ 0.175 Inch (in) Inner Diameter (A) Carbon Steel Washer |

DL-M5-3/16 Disc-Lock™ 0.203 Inch (in) Inner Diameter (A) Carbon Steel Washer |

DL-M6-1/4 Disc-Lock™ 0.262 Inch (in) Inner Diameter (A) Carbon Steel Washer |

DL-M8-5/16 Disc-Lock™ 0.326 Inch (in) Inner Diameter (A) Carbon Steel Washer |

|||||

| Description |

N/A

Features & Benefits

Disc-Lock® Locking Washer Junker Test Disc-Lock® Wedge Locking Washers have been tested on a Junker Vibration Machine. The Junker test considered the most severe vibration test for bolted joints according to DIN 65151, is used to determine the point at which a bolted joint loses its preload when subjected to shear loading due to transverse vibration. When tested against a standard washer using the Junker test, Disc-Lock® Wedge Locking Washers remained secure under severe vibration conditions, while the standard washer loosened significantly. Proven Applications Disc-Lock® Wedge Locking Washers outperform conventional, split-ring, and other style washers in a wide variety of high stress, corrosive, and vibration-sensitive applications including:

When installing Disc-Lock® Washers in a common application, expect an increase in required torque over recommended installation torque to achieve proper clamp load and maximum joint safety. Due to varying installation conditions and customer-specific applications, additional information and torque recommendations are available by contacting Engineering support at Disc-Lock®. Note Weight and thickness of pairs will vary slightly with gauge of metal.

|

|||||||||

| Dimensions |

N/A

|

|||||||||

| Brands | N/A Disc-Lock™ | |||||||||

| Size | N/A #6 3 mm | N/A #8 4 mm | N/A 3/16 in5 mm | N/A 1/4 in6 mm | N/A 5/16 in8 mm | |||||

| Inner Diameter (A) | N/A 0.150 in3.81 mm | N/A 0.175 in4.45 mm | N/A 0.203 in5.15 mm | N/A 0.262 in6.66 mm | N/A 0.326 in8.28 mm | |||||

| Outer Diameter (C) | N/A 0.340 in8.64 mm | N/A 0.340 in8.64 mm | N/A 0.401 in10.18 mm | N/A 0.495 in12.57 mm | N/A 0.628 in15.95 mm | |||||

| Thickness (EE) | N/A 0.080 in2.03 mm | N/A 0.080 in2.03 mm | N/A 0.080 in2.03 mm | N/A 0.127 in3.22 mm | N/A 0.142 in3.60 mm | |||||

| Box Quantity | N/A 3,000 | |||||||||

| Material | N/A 1010 Carbon Steel | |||||||||

| Industry Standards/Compliance | N/A ISO 9001:2008 ISO TS16949 MIL-STD-1312-7 RoHS | |||||||||

| Package Type | N/A Box | |||||||||

| Features and Benefits |

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

|||||

| Proven Results |

N/A

Disc-Lock™ Locking Washer Junker Test Disc-Lock™ Wedge Locking Washers have been tested on a Junker Vibration Machine. The Junker test, considered the most severe vibration test for bolted joints according to DIN 65151, is used to determine the point at which a bolted joint loses its preload when subjected to shear loading due to transverse vibration. When tested against a standard washer using the Junker test, Disc-Lock™ Wedge Locking Washers remained secure under severe vibration conditions, while the standard washer loosened significantly. |

|||||||||

| Proven Applications |

N/A

Disc-Lock™ Wedge Locking Washers outperform conventional, split-ring, and other style washers in a wide variety of high stress, corrosive, and vibration-sensitive applications including:

|

|||||||||

| Installation |

N/A

|

|||||||||

| Torque Guidelines | N/A When installing Disc-Lock™ Washers in a common application, expect an increase in required torque over recommended installation torque to achieve proper clamp load and maximum joint safety. Due to varying installation conditions and customer specific applications, additional information and torque recommendations are available by contacting Engineering support at Disc-Lock™. | |||||||||

| Note |

N/A

Weight and thickness of pairs will vary slightly with gauge of metal.

Disc-Lock Wedge Locking Washers are also available through our Made in the U.S.A. product line |

|||||||||

| Resources |

N/A

Disc Lock Washer Catalog |

|||||||||

|

|

||||||||||