- All Categories

-

Fasteners for Thin Sheet Attachments

-

Blind Rivet Nuts

-

Round Body Rivet Nuts

-

Optisert Series

- Optisert -- Open End (Metric) | Steel (308 Items)

- Optisert -- Open End (Inches) | Steel (144 Items)

- Optisert -- Open End (Metric) | Stainless Steel (18 Items)

- Optisert -- Open End (Inches) | Stainless Steel (27 Items)

- Optisert -- Closed End Sealed (Metric) | Steel (302 Items)

- Optisert -- Closed End Sealed (Inches) | Steel (144 Items)

-

CAL Series

- CAL Series - Steel (Inches) | Large Flange Knurled Body Thin Wall Series (268 Items)

- CAL Series - Steel (Metric) (368 Items)

- CAL Series - Aluminum (Inches) (132 Items)

- CAL Series - Aluminum (Metric) (368 Items)

- CAL Series - Stainless Steel (Inches) (10 Items)

- CAL Series - Stainless Steel (Metric) (6 Items)

-

CAK Series

- CAK Series - Steel (Inches) | Small Flange Knurled Body Thin Wall Rivet Nut (2256 Items)

- CAK Series - Steel (Metric) (293 Items)

- CAK Series - Aluminum (Inches) (2256 Items)

- CAK Series - Aluminum (Metric) (293 Items)

- CAK Series - Stainless Steel (Metric) (10 Items)

-

CA Series

- CA Series - Steel (Inches) | Heavy Duty Rivet Nut Flat Head, Large Flange, Smooth Shank (193 Items)

- CA Series - Aluminum (Inches) (193 Items)

- CA Series - Stainless Steel (Inches) (193 Items)

-

CAO Series

- CAO Series - Steel (Inches) | Small Flange, Smooth Body, Thin Wall Rivet Nut (134 Items)

- CAO Series - Steel (Metric) (162 Items)

- CAO Series - Aluminum (Inch) (134 Items)

- CAO Series - Aluminum (Metric) (162 Items)

-

CFW/CAW Series

- CFW/CAW Series - Steel (Inches) | Cadmium Free Diamond Knurled Body 360° Swaging Rivet Nut (7 Items)

- CFW/CAW Series - Steel (Metric) (5 Items)

- CFW/CAW Series - Aluminum (Inches) (7 Items)

- CFW/CAW Series - Aluminum (Metric) (5 Items)

- CFW Series - Stainless Steel (Inches) (7 Items)

- CFW/CAW Series - Stainless Steel (Metric) (5 Items)

-

CFT/CAT Series

- CFT/CAT Series - Steel (Inches) | Cadmium Free Small Flange 360° Swaging Rivet Nut (9 Items)

- CFT/CAT Series - Steel (Metric) (7 Items)

- CFT/CAT Series - Aluminum (Inches) (9 Items)

- CFT/CAT Series - Aluminum (Metric) (7 Items)

- CFT Series - Stainless Steel (Inches) (9 Items)

- CFT Series - Stainless Steel (Metric) (7 Items)

-

CPB Series Rivet Nuts

- CPB Series - Steel (Inches) (162 Items)

- CPB Series - Steel (Metric) (325 Items)

-

CPN Series Rivet Nuts

- CPN Series - Steel (Inches) | Straight Shank Slotted Body Rivet Nut (162 Items)

- CPN Series - Steel (Metric) (325 Items)

-

UPO Tubtara®

- UPO Series - Steel (18 Items)

- UPO Series - Aluminum (15 Items)

- UPO Series - 304 Stainless Steel (11 Items)

- UPO Series - 316 Stainless Steel (3 Items)

-

UFO Tubtara®

- UFO Series - Steel (13 Items)

- UFO Series - Aluminum (11 Items)

- UFO Series - 304 Stainless Steel (6 Items)

-

UKO Tubtara®

- UKO Series - Steel (8 Items)

- UKO Series - Aluminum (4 Items)

- UKO Series - 304 Stainless Steel (5 Items)

- UKO Series - 316 Stainless Steel (3 Items)

- UKO Series (Inches) - 304 Stainless Steel (3 Items)

-

UPO RS Tubtara®

- UPO RS Series - Steel (10 Items)

-

UFO RS Tubtara®

- UFO RS Series - Steel (10 Items)

-

CLM

- CLM Series - Steel (5 Items)

- CLM Series - Aluminum (5 Items)

-

CKM

- CKM Series - Steel (5 Items)

- CKM Series - Aluminum (5 Items)

-

Optisert Series

-

Hex Body Rivet Nuts

-

FHL Series

- FHL Metric Series (271 Items)

- FHL Inch Series (1042 Items)

-

FHK Series

- FHK Metric Series (307 Items)

- FHK Inch Series (1181 Items)

- LRGH Series (4 Items)

-

CAH Series

- CAH Series - Steel (Inches) (2257 Items)

- CAH Series - Aluminum (Inches) (2256 Items)

- CAH Series - Steel (Metric) (293 Items)

- CAH Series - Aluminum (Metric) (293 Items)

-

HUKO Series

- HUKO Series (Inches) (3 Items)

- HUKO Series (Metric) (8 Items)

- HUPO Series (10 Items)

-

HUKO Stainless Series

- HUKO Series - 304 Stainless Steel (6 Items)

- HUKO Series - 316 Stainless Steel (3 Items)

-

HUPO Stainless Series

- HUPO Series - 304 Stainless Steel (4 Items)

- HUPO Series - 316 Stainless Steel (3 Items)

-

CFH Series

- CFH Series - Steel (Inches) (15 Items)

- CFH Series - Steel (Metric) (12 Items)

- CFHD Series (6 Items)

-

FHL Series

-

Large Size Rivet Nuts

- Round Body Large Size Rivet Nuts (5 Items)

- Full Hex Body Large Size Rivet Nuts (4 Items)

-

RIV-FLOAT® Rivet Nuts

- RIV-FLOAT® Rivet Nuts (251 Items)

- RIV-FLOAT®-Short Series (6 Items)

- Rivet Nut Studs

-

NAS/MS Rivet Nuts

- NAS 1329 Flat Head Style (46 Items)

- NAS 1330 Countersunk Head Style (46 Items)

- Specialty Fastener Solutions (13 Items)

-

ATLAS MaxTite® Rivet Nuts

-

Countersunk Head

- Countersunk Head Threaded Insert - Open End Keyless - Unified (460 Items)

- Countersunk Head Threaded Insert - Open End Keyed - Unified (460 Items)

- Countersunk Head Threaded Insert - Closed End Keyless - Unified (460 Items)

- Countersunk Head Threaded Insert - Closed End Keyed - Unified (460 Items)

- Countersunk Head Threaded Insert - Open End Keyless - Metric (386 Items)

- Countersunk Head Threaded Insert - Open End Keyed - Metric (386 Items)

- Countersunk Head Threaded Insert - Closed End Keyless - Metric (386 Items)

- Countersunk Head Threaded Insert - Closed End Keyed - Metric (387 Items)

-

Flathead

- Flathead Threaded Insert - Open End Keyless - Unified (532 Items)

- Flathead Threaded Insert - Open End Keyed - Unified (532 Items)

- Flathead Threaded Insert - Closed End Keyless - Unified (532 Items)

- Flathead Threaded Insert - Closed End Keyed - Unified (532 Items)

- Flathead Threaded Insert - Open End Keyless - Metric (386 Items)

- Flathead Threaded Insert - Open End Keyed - Metric (386 Items)

- Flathead Threaded Insert - Closed End Keyless - Metric (386 Items)

- Flathead Threaded Insert - Closed End Keyed - Metric (386 Items)

-

Countersunk Head

-

Round Body Rivet Nuts

- Fasteners for Plastics & Composites

-

Clinch Nuts

- ACN Series High Strength Clinch Nut Series (6 Items)

- ARN Series Universal Riveting Nut Series (5 Items)

- ASN Series Serrated Style Clinching Nut Series (4 Items)

- Load Bearing Nut Plates and Stud Plates

- Compression Limiters

-

Blind Rivet Nuts

-

Vibrational Loosening Prevention - Wedge Locking Technology

- TEC Series® Wedge Locking Washers

-

Disc-Lock® Wedge Locking Washers

- Disc-Lock® Carbon Steel Washers (17 Items)

- Disc-Lock® Stainless Steel Washers (10 Items)

-

Disc-Lock® Wedge Locking Nuts

- Disc-Lock® Two-Piece Wedge Locking Nuts (18 Items)

- Disc-Lock® Safety Wheel Nut

- Disc-Lock™ Heavy Hex Nuts (6 Items)

- Disc-Lock® Bolts

-

Fastener Installation Systems

-

Rivet Nut Hand Tools

- Rivet Nut Hand Tool (16 Items)

- DLHT Double Lever Hand Tool (12 Items)

- DRHT Double Ratchet Hand Tool (15 Items)

- LHF 202 Hand Tool

-

Pneumatic Tools (Spin-Spin)

- SSG 800 Pistol Style Series (20 Items)

- SSG 900 Inline Style Series (17 Items)

- SSG 910 Inline Right Angle Style Series (17 Items)

-

Hydro-Pneumatic Tools

- MS 100 Rivet Nut Installation Tool 5/16-18-1/2-13 (M8-M14) (12 Items)

-

FLEX-5 Series Rivet Nut Installation Tool 4-40 to 3/8-24 (M3 to M10)

- FLEX-5S Pull to Stroke Installation Tool (17 Items)

- FLEX-5P Pull to Pressure Installation Tool (17 Items)

- FLEX-18 Rivet Nut Installation Tool 5/16-18 - 3/4-10 (M8-M20) (12 Items)

- Automation

-

Rivet Nut Hand Tools

-

Fasteners for Thin Sheet Attachments

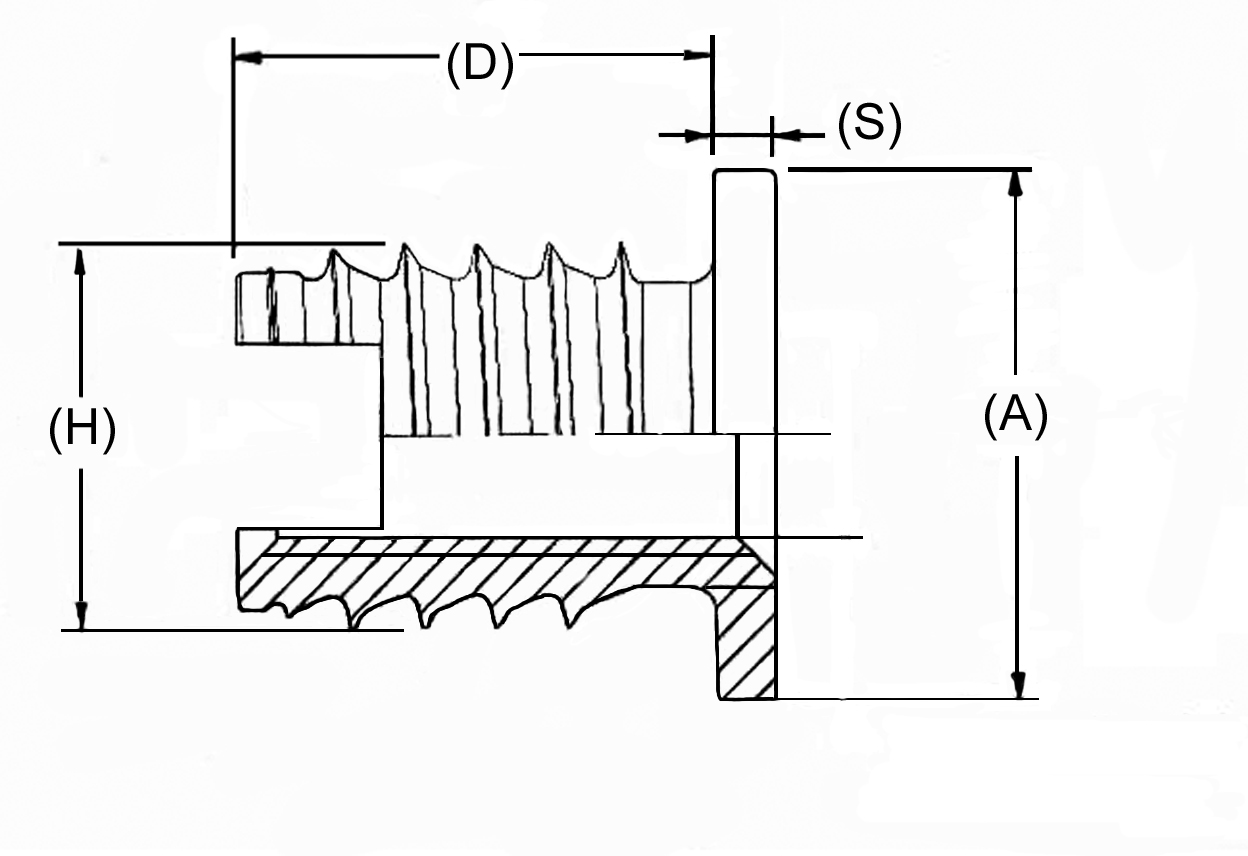

- Designed for SMC, Thermoset, and other brittle plastics

- Flange provides larger bearing surface

- Installed with a tap wrench or drill press with tapping head

- Class 2B per ANSI/ASME B1.1

Thread In - this method is reserved for the B1T and B2T insert styles. A tool will thread the inserts into the boss hole and the slots on the body will cut a thread into the plastic. This method is good for thermosets and other rigid plastics. An adhesive can be added to the outside thread to bond the insert into the plastic; further improving insert retention within the base material.

Applications for Threaded Inserts for Plastic vary from communication equipment, the automotive industry, computer industry, and anywhere where strong durable threads are required in plastics.

Unit of Measure

Dimensions |

N/A

|

Thread Size |

N/A 5/16-18 UNC |

ØH ±0.004 |

N/A 0.472 Inch |

D± 0.005 |

N/A 0.591 Inch |

ØA ±0.005 |

N/A 0.591 Inch |

S ±0.004 |

N/A 0.055 Inch |

Hole Depth

|

N/A 0.709 Inch |

Minor Diameter

|

N/A .252 / .265 Inch |

Recommended Hole Size for Thermoset Material

|

N/A 0.448 Inch |

|

N/A

B2T-3118-591.pdf |